De-bug Uk L2000

Availability: In Stock

NATO Part Number: 2910-98-202-6290

How De-Bug Works

De-BugTM is a time proven propriety product, not a process description or generic name. And, it takes more than a magnet to make a De-Bug. Only genuine De-Bug units have the exclusive TRI-MAGTM and MULTI-MAGTM Bug Killer Packs.

De-BugTM is a time proven propriety product, not a process description or generic name. And, it takes more than a magnet to make a De-Bug. Only genuine De-Bug units have the exclusive TRI-MAGTM and MULTI-MAGTM Bug Killer Packs.

Technology using magnetic flux fields to combat (microorganisms and their associated problems) in aqueous fluids has been developed in New Zealand. Until recently, this technology was relatively unknown in the U.S.. However, the theory that magnetic flux fields inhibit microorganism growth and survival has long been noticed and has now been proven.

There is an old story about a Scottish marine engineer who observed that the fuel oil supply line and filters to his port generator had fewer clogging problems than to his starboard generator. He determined that the difference between the two fuel supply systems was that the port fuel line passed through a magnetic flux field. The engineer concluded that somehow this controlled the material that caused the fuel line and filter clogging.

Over the years, many have tried to develop a device that could duplicate this phenomenon, with limited success.

While designing the Debug unit it became evident early on that a single magnet device could not produce the desired efficiency, and that an oscillating field was the most effective because microorganism cells could not react quickly enough to a rapidly changing magnetic field.

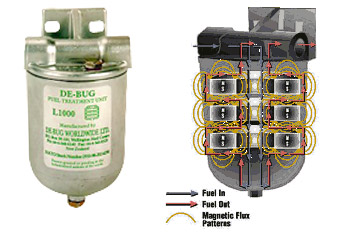

An oscillating magnetic flux field effect could be simulated by carefully directing contaminated fuel flow through a stack of multiple permanent magnets. By directing microorganisms into and out of the flux field, a simulated oscillating field was achieved. Shortly after, the De-BugTM Model L-1000 Fuel Decontamination Unit was launched which fully incorporated this concept. The success of this unit is based on a specific flow rate through a stack of three ferrite-metal ceramic-coated permanent magnets known as the "TRI-MAG Bug Killer PakTM", which achieves a microorganism kill rate efficiency of nearly 100% (97.6%) in one pass. These permanent magnets have a service life of 20-50+ years.

Housed within the De-Bug Fuel Decontamination Unit, the "TRI-MAGTM Pack consists of three flat donut shaped permanent magnets, manufactured from ferrite-metal and ceramic-coated, stacked each above the other. The spacing between the magnets is scientifically determined in order to produce the optimum flux field density. The magnets are arranged and held in place with special spacers in such a way that a north pole always faces a south pole. These spacers are manufactured from Acetyl M90 plastic. As with all other special engineering materials used in the De-Bug, this material is used for its resistance to diesel fuel and similar hydrocarbon based products. In addition, Acetyl M90 plastic is used for its adaptability to cope with various applications such as the harsh marine environment, the mining industry, and agricultural equipment. Acetyl M90 Plastic is also particularly resistant to environmental stress cracking and numerous chemicals usually associated with diesel fuels. Further, it is capable of withstanding extreme temperatures.

Within the De-Bug unit, the spacers perform two functions. First, to create and maintain proper distance between the magnets. Second, to direct fuel flow through the magnetic flux field. As the fuel passes through the De-Bug, any microorganisms are subject to a rapid magnetic field change four separate times or four oscillations. This unique patented design (US patents 5,248,437 and 5,055,188, New Zealand patent 231876), exclusive to De-Bug products, is what enables De-Bug Products to achieve their unparalleled effectiveness and success. De-Bug holds exclusively, the patent for all multiple magnet device designs, which are incorporated in every De-Bug Product. If it does not have a TRI-MAGTM or MULTI-MAGTM Pack, then it is not a De-BugTM Product.

- Application: For Diesel fuel, marine diesel, light oil and gas oil

- Flow rate: Recommended up to 2000 litres per hour

- Weight: 7.5 Kilograms

- Size: 152mm diameter by 360mm high by 170mm deep

- Port Size: 1” Hydraulic Connectors

- Operating Pressure: Up to 50psi

- Materials: 316 Stainless Steel (powder coated)

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Ask a question about De-bug Uk L2000